Radiation heat transfer and convection heat transfer are today's topic. This article explains how heat flux sensors are capable of measuring different types of heat flux. To understand thermal processes, it is of great importance to understand the difference between the radiative heat flux and the convective heat flux. Before explaining the processes of measuring convective heat flux and radiative heat flux, a short introduction to the physics.

Convective heat flux

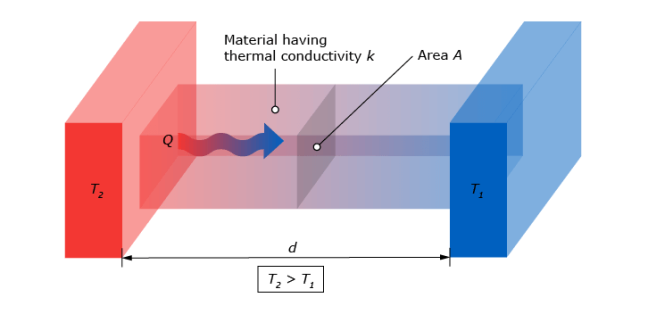

The convective heat flux of an object is the thermal energy that is exchanged between a solid and a gas or liquid. This flow of thermal energy is always directed from hot to cold.

A first distinction can be made between forced convection and natural convection. Natural convection is caused by natural phenomena like the change in density of a fluid when its temperature changes. This often causes a circular motion in the fluid. Forced convection occurs when liquids or gasses are forced into motion by something external like fans, pumps or boilers.

The second distinction to be made is internal or external convection. Internal convection occurs when a fluid is surrounded by solid material and external convection describes a solid material being surrounded by a fluid.

Radiative heat flux

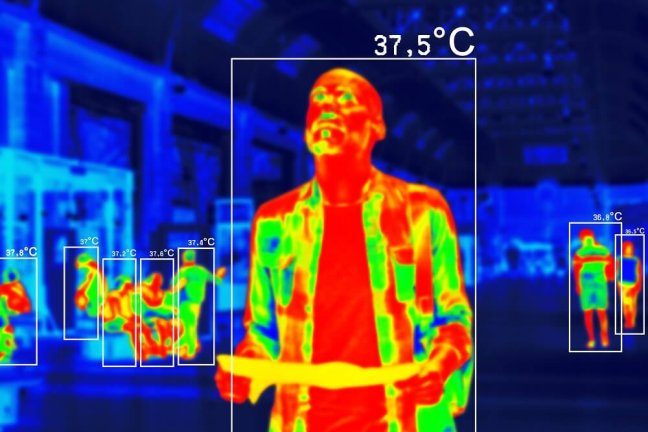

Radiative heat flux is called radiation. Radiation is everywhere. As long as an object has a temperature, it emits radiation. Radiation is the transfer of thermal energy in the form of electromagnetic waves. These waves have a wavelength that determines what kind of radiation is emitted. The higher the temperature of the object emitting the radiation, the shorter the wavelength of the radiation.

The light we use to see is also part of the electromagnetic spectrum. Many devices that we use today make use of emitting radiation and receiving radiation to exchange information. Although solar radiation, radio waves and x-rays have very different causes and purposes, they are part of the same phenomenon: Radiation.

If you would like to know about conduction, the third type of heat flux, and learn more about convection and radiation, please read the article: What is heat flux?

Example measuring heat flux: a fridge

As said before, it can be useful to know the amount of thermal energy that an object emits or receives. Let’s say that a fridge manufacturer would like to know how much thermal energy is lost through the insulating walls of the fridge. In this case, the heat flows from outside of the fridge to the inside of the fridge. Logically, the more thermal energy that flows through the walls, the more power is needed to keep the fridge cold. In this case it is important to know the amount of energy that is lost by convection and radiation independently.

The Hukseflux FHF05-series heat flux sensors, the HFP heat flux sensors and BLK - GLD stickers are capable of answering these types of questions.

The heat flux sensors are small, easy to install devices. By adding a thin layer of a prescribed adhesive, it is easy to stick the sensors onto a surface. In this case, the surface is the wall of the fridge from which we want to know the two types of heat flux that it emits and receives.

If you want to make a distinction between convective heat flux and radiative heat flux, two sets of sensors should be placed beside each other. Make sure that the sensors are installed as prescribed in the provided manuals. The two sets of sensors are placed on the same surface, so the assumption can be made that the heat fluxes measured by the sensors are initially identical. After both sensors have been installed, one should be covered with a Hukseflux BLK ‘black’ sticker and the other with a GLD ‘gold’ sticker.

These stickers make it possible to separate the convective heat flux from the radiative heat flux through this particular surface. The BLK black sticker is sensitive to radiative heat flux and convective heat flux. The GLD gold sticker is only sensitive to convective heat flux. In short, the difference in measured heat flux of both sensors is the radiative heat flux and the measured heat flux of the GLD gold stickered sensor is the convective heat flux.

After measuring the convective heat flux and the radiative heat flux

For the fridge manufacturer, the following conclusions could be drawn from these measurements. If the incoming heat flux mainly consists of radiative heat flux, a solution could be to paint the exterior of the fridge white as this color absorbs the least radiation. Another option is to make the outer layer of the fridge from a reflective metal like polished aluminum. This should result in reflecting more of the incoming radiation, keeping the fridge cool with a lower energy consumption.

If the incoming heat flux mainly consists of convective heat flux, than it is a good idea to make the exterior of the fridge as smooth as possible. A rough exterior leads to a more turbulent boundary layer of air. The more turbulent this boundary layer is, the more mixing of air occurs. This mixing enforces the convective heat flux. As this is unwanted for the design of a fridge, a smooth exterior should be applied. Another option could be to prevent any forced convection around the fridge when placing it. Do not place it directly under or in front of a fan as this too will increase the convective heat flux.

Most fridge manufacturers know this, hence most fridges have a smooth white exterior.

Simplistic separation of heat fluxes

The fastest and easiest way separating the two types of heat flux is based on a few assumptions, listed below:

- The surfaces underneath both sensors have the exact same temperature

- The BLK black sticker has perfect absorption

- The GLD gold sticker has perfect reflection

These assumptions are not always completely accurate but are sufficient for the average user. This approach leads to moderate-accuracy results. It can be very useful for estimating and verifying the orders of magnitude of further high-accuracy measurements.

For moderate-accuracy measurements, the following formulas are used:

HFblack = HFconvective + HFradiative

HFgold = HFconvective

HFradiative = HFblack - HFgold

With “HF” = Heat Flux

Inside the heat flux sensors there is a thermopile. A thermopile is capable of converting the amount of heat flux through the sensor into an output voltage. The ratio of output voltage to heat flux is called the sensitivity, ‘S’. This sensitivity is determined individually for every type of sensor by calibration. For more information on the workings of a thermopile, please read: How to measure heat flux?

High accuracy measurements of conductive and radiative heat flux

If a high accuracy measurement is needed, it is essential to understand the following statements:

- Reflection and absorption of both GLD and BLK stickers may not be perfect.

- The temperature of the sensor is not always the same as the temperature of the heat sink on which it is placed. The difference can be calculated from heat flux, temperature and thermal resistance of the sensor. The temperature difference becomes greater with higher heat fluxes.

- A BLK sticker does not only receive radiation, but also emits radiation depending on its temperature. The measured radiation is the net result of both incoming and outgoing radiation.

- The sensitivity of a heat flux sensor is not constant. It can change with the operating temperature. The operating temperature cannot be too far away from the temperature at which it was calibrated.

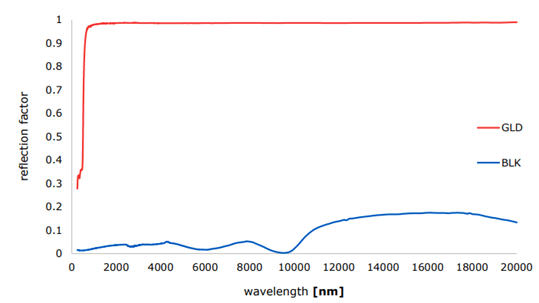

To give an understanding of the first statement, please look at the image below. Different wavelengths are reflected in different amounts by both colors. The GLD sticker especially becomes unreliable around the UV spectrum, or around 400 nanometers. The BLK sticker, of which reflection is unwanted, is less accurate but stable at all wavelengths.

With regard to the second statement, it is important that both sensors are installed on the same heat sink. If possible, it helps to place an aluminum plate of 1 mm thick between the sensor and the surface to be measured. If this is ensured, it is safe to assume the temperature difference to be smaller than 2˚ C. If you are interested in the calculations as to why this is acceptable, please read chapter 3.3 of the article BLK-GLD sticker series manual (see link below).

The Hukseflux BLK – GLD sticker series, usable for separate measurements of convective heat flux and radiative heat flux, can be found here: BLK – GLD sticker series.