Validating liquid hydrogen transport simulations with heat flux sensors

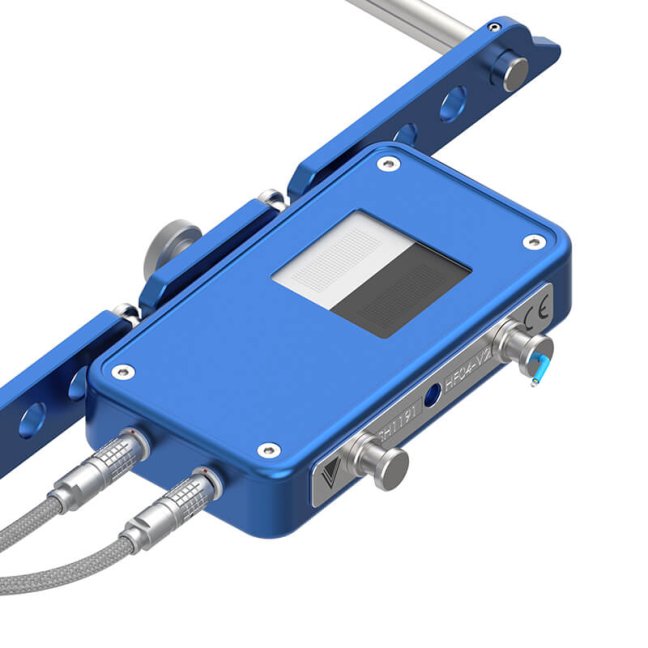

Hukseflux FHF05 series heat flux sensors are being used by leading companies in transportation technology to enhance safety and efficiency of liquefied hydrogen transport systems. Reliable heat flux measurements are critical for validating thermal behaviour in cryogenic tanks during self-pressurisation and sloshing. The FHF05 series are selected for their flexibility and high accuracy.

Read the full article here: Validating liquid hydrogen transport simulations with heat flux sensors (PDF)

Liquefied hydrogen

Hydrogen fuel is a promising carbon-free alternative being researched by the energy industry. To meet global demand, large-scale infrastructure for liquefied hydrogen (LH2) transport is needed. Liquefied hydrogen, with its high energy density, is ideal for efficient storage and shipping. However, storing liquefied hydrogen at cryogenic temperatures (-253 °C) poses significant challenges. Even minor heat penetration into storage tanks can cause the liquefied hydrogen to evaporate, leading to pressure build-up known as self-pressurisation. During transport, liquid movement or sloshing can further complicate pressure management and affect tank stability.

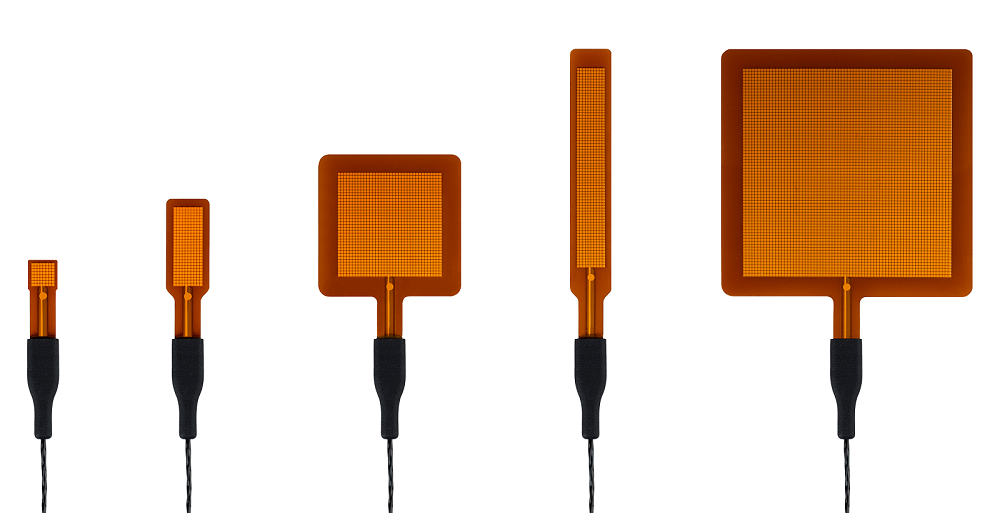

dimensions and sensitivities, so you can choose the right sensor for your application.

To address these challenges, advanced multiphysics simulation models, such as Computational Fluid Dynamics (CFD), are employed to predict temperature and pressure behaviours within cryogenic tanks. Leading companies in transportation technology, use these simulations to design safe and efficient storage systems. To ensure the accuracy of their models, they validate them through experimental testing using Hukseflux’s FHF05 series heat flux sensors (see Figure 1), providing critical data to refine simulation models and enhance tank designs.

Liquefied hydrogen storage

Liquefied hydrogen is stored at -253 °C to maintain its liquid state, requiring highly insulated tanks to minimise heat transfer. Liquefaction shrinks hydrogen’s volume to about 1/800th of its gaseous form, making it ideal for compact storage. However, heat penetration can cause boil-off, where the liquid evaporates, increasing internal pressure (self-pressurisation).

1.250 m³ tank designed for cryogenic storage at -253 °C.

Image credit: Kawasaki.com

Sloshing, the movement of liquid during transport, can also affect tank stability and thermal dynamics. To ensure safety, tanks must incorporate advanced insulation, such as double-shell vacuum-insulated designs, and robust pressure relief systems. In 2022, Kawasaki’s Suiso Frontier was the world’s first liquid hydrogen carrier ship with a capacity of 1.250 m3. It achieves low boil-off rates (0.3% per day), showcasing its expertise in thermal management. Their new design employs 40.000 m3 spherical tank designs, with four per ship, totalling 160.000 m3 capacity.

Simulation technology for tank behaviour

As tank capacity increases, precise thermal management becomes more important. CFD is widely used for modelling complex heat and mass transfer processes. It allows engineers to simulate the interactions between heat transfer, fluid dynamics, and phase changes within the tank. By simulating these conditions, engineers can optimise insulation designs, ensuring they withstand pressure build-up and liquid movement without compromising safety or efficiency. This reduces the need for costly physical prototypes and enables rapid design iterations.

Experimental validation with FHF05 series heat flux sensors

To validate these simulations, a small-scale test tank filled with water can be used before testing with liquid hydrogen. Using water is safer and cheaper than handling liquid hydrogen at -253 °C. The experimental setup involves filling the tank with water and adding water vapor to simulate self-pressurisation, mimicking the pressure build-up caused by heat penetration in a real tank. After reaching vapor-liquid equilibrium, the tank is sloshed to imitate liquid movement during transport. A key component of this setup is the FHF05-15x85 heat flux sensor, attached to the inner tank wall to measure heat transfer during both self-pressurisation and sloshing. The collected heat flux data is compared with simulation results to assess the model’s accuracy.

Heat flux sensor selection and benefits

Rather than relying solely on temperature probes, leading companies in transportation technology choose heat flux sensors to measure wall heat transfer through the tank wall. A heat flux sensor gives real-time data (in W/m2) on heat gain or loss, often before any temperature change is apparent. Hukseflux’s FHF05 series heat flux sensors are particularly suited for this application due to their integrated temperature sensor and thin, flexible design. This allows for a complete view of the thermal behaviour and easy mounting onto the curved tank wall without disturbing the thermal boundary layer. The sensor’s IP67 protection rating ensures reliability in the humid and fluctuating conditions of the test setup. While the FHF05 series is rated for continuous operation between –70 °C and +120 °C (with short-term use between –160 °C and +150 °C), the sensors have also demonstrated stability in cryogenic applications beyond this range. However, it is important to note that at extremely low temperatures, the sensor material becomes brittle and loses its flexibility, requiring careful handling.

Conclusion

Transporting liquefied hydrogen introduces unique challenges due to its extremely low temperatures. Advanced simulations are crucial for designing safe and efficient storage tanks, but their accuracy must be validated through experimental data. The use of Hukseflux’s heat flux sensors by leading companies in transportation technology demonstrates the value of high-quality heat flux measurements in this validation process. The FHF05 series heat flux sensors provide the flexibility, accuracy, and robustness needed to measure heat transfer in a small-scale test tank. For those seeking to optimise their own thermal management systems, Hukseflux offers a range of sensors and expert advice. Contact our team for personalised guidance on selecting the right sensors for your application.

Read the full article here: Validating liquid hydrogen transport simulations with heat flux sensors (PDF)